The Architect’s Guide to Seamless Access Points for High-Rise & Mixed-Use Canadian Projects Posted by Best Access Doors Canada on 10th Feb 2026

Seamless access panels help Canadian architects maintain clean interior lines, while still meeting fire, maintenance, and inspection requirements in high-rise and mixed-use projects.

But when access is treated as an afterthought, poorly placed panels can clash with architectural finishes and draw attention away from the spaces you’ve worked hard to refine.

It can also make it hard to demonstrate that your design supports safe operation, clear access to services, inspection readiness, and long-term usability.

In this guide, we’ll explain why seamless access panels are crucial in Canadian high-rise projects, what can go wrong when mixed-use building access solutions are addressed late, and how BAC-IVH and BAC-IVHFH support concealed access in complex buildings.

Why Are Seamless Access Points Critical in High-Rise and Mixed-Use Architectural Design?

Seamless access points are crucial in high-rise and mixed-use buildings because they preserve clean architectural lines while ensuring there’s reliable and safe access to the systems that keep the building running.

Every tower and podium stack is equipped with a range of services, including fire protection, plumbing, HVAC, electrical, data, and life-safety systems. All those lines need maintenance, inspection, and occasional replacement over the building’s lifecycle.

Because of that, it’s not enough to think about access at the end of the project. You need to decide how and where access will be provided early in design, before walls and ceilings are closed in. That way, you can preserve your design intent while still supporting long-term serviceability.

If you’re designing your next mixed-use development, this is the right stage to explore our seamless access panel solutions built for Canadian high-rise and mixed-use architecture.

When Should Architects Coordinate Access Panels to Protect Design Intent and Approvals?

Canadian architects should coordinate access panels as early as schematic design and certainly by design development, so that access requirements are incorporated into plans, elevations, and specifications before tender.

If access is left to late RFIs, it tends to show up as surface-mounted boxes or ad-hoc hatches that disrupt your carefully composed ceilings and walls.

Instead, you should build your architectural access panels into your base design workflows:

- During schematic design to identify major service zones and flag which walls and ceilings are likely to carry fire-rated wall assemblies or acoustic separations.

- In design development to help you coordinate access panel locations with MEP engineers so that equipment, valves, and junctions are reachable without cutting into finished surfaces later.

- At the construction documents stage to confirm compatibility with mixed-use occupancy, where different tenants and users may require different access control strategies.

What Challenges Arise When Access Requirements Are Addressed Late in Design?

When requirements for high-rise access doors are addressed late, they often result in avoidable rework, coordination headaches, and visible compromises that undermine the final project.

Some of the most common problems include:

- Unplanned penetrations into fire-rated assemblies: If access doors are added after wall types and fire separations have been specified, there’s a risk that the selected access door won’t match the rating or the tested assembly. This can trigger redesigns, additional firestopping details, or even failed inspections when authorities review the completed work.

- Awkward, protruding panels in high-traffic areas: When access isn’t coordinated early, contractors often end up installing surface-mounted access doors in corridors, amenity spaces, and retail interfaces as a quick fix. These panels can introduce long-term trip hazards, impact risks, and visual clutter in spaces that were meant to feel clean and well-organized.

- Change orders and schedule delays: Late coordination can lead to re-framing, re-routing services, or rebuilding sections of the ceiling to provide adequate access. Each adjustment adds cost and can delay occupancy at a time when housing and mixed-use delivery timelines are already under pressure.

How Do BAC-IVH and BAC-IVHFH Support Concealed Access in Complex Buildings?

BAC-IVH and BAC-IVHFH support concealed access in complex buildings by combining drywall inlay construction, minimal reveals, and hidden hardware so that access points sit almost invisible within walls and ceilings.

Both models are part of Best Access Doors’ Invisa Hatch™ family of concealed access doors solutions.

Some of the core features they share include:

- Architecturally discreet design

- Welded high-grade aluminum frame with inlayed gypsum drywall, so the panel reads as part of the wall or ceiling.

- A reveal of just 1/16" (1.59 mm) between the outer frame and door hatch, creating a subtle shadow line instead of a visible door edge.

- Flush installation in ceilings and walls to support continuous architectural finishes in corridors, suites, and public spaces.

- Concealed operation and safety

- Concealed snap locks that open when pressure is applied to the spring-loaded latch side, keeping faces clean and latch-free.

- On sizes 12" x 12" and up, an integrated safety system helps prevent accidental opening when the hatch is removed. But this must be reattached when the panel is reinstalled.

- Flexible sizing and board options

- Custom sizes available so you can align openings with stud layouts, equipment clearances, and finish grids.

- Options for moisture-resistant, mildew-resistant, and cement board inserts to suit washrooms, service areas, and other demanding environments in mixed-use buildings.

Where BAC-IVH and BAC-IVHFH differ is in how the door leaf behaves once you open it, and that’s where architects gain useful flexibility for different service conditions.

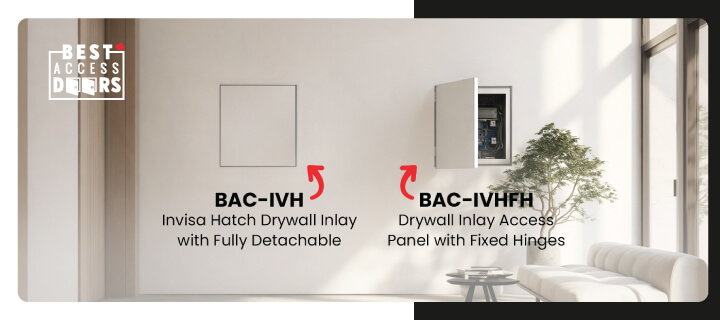

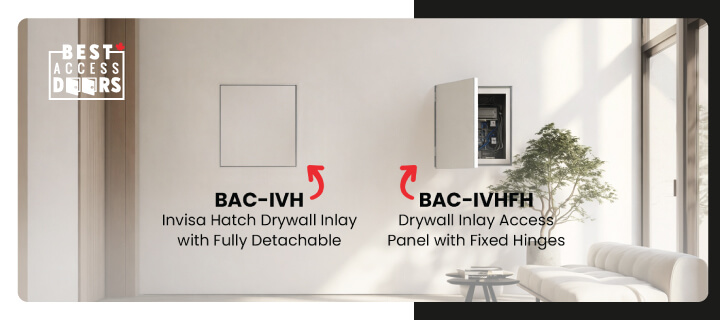

BAC-IVH: Fully Detachable, Flush, and Tile-Ready

The Invisa HatchDrywall Inlay with Fully Detachable is ideal for locations where you expect occasional but significant interventions, such as equipment swaps or larger inspections, and want the opening to visually disappear the rest of the time.

Key characteristics include:

- Fully detachable panel door

- The door leaf can be completely removed, creating a wide, unobstructed opening. This is especially helpful for equipment replacement or accessing congested risers where a swinging leaf would get in the way.

- Concealed, push-to-latch operation

- A pressure-assisted push-to-latch mechanism provides tool-free access from the finished side.

- Alternate lock and latch combinations are available where additional security or controlled access is required, without compromising the clean face.

- Finish-friendly design

- Compatible with both ½" and 5/8" drywall inserts, the panel is available in a tile-ready configuration. This allows tile or other surface finishes to seamlessly transition across the panel for a blended, high-end look.

BAC-IVHFH: Fixed Hinges for Controlled, Frequent Access

The BAC-IVHFH Invisa Hatch™ Drywall Inlay Access Panel With Fixed Hinges is designed for situations where the door should remain attached and be operated regularly, such as high-wall locations, utility corridors, or frequently serviced zones in high-rise and mixed-use projects.

Its distinct features include:

- Fixed hinge with touch-latch operation

- A hinge-attached leaf opens smoothly with a touch latch, keeping the door supported during use, which is particularly valuable for overhead installations where safety and control are crucial.

- Clean, minimal appearance in visible areas

- Hidden mechanisms and the same tight reveal help the panel sit comfortably within premium interiors, where you need regular access but don’t want obvious hardware or bulky frames.

- Project-specific sizing and performance options

- Custom sizing allows alignment with ceiling grids, millwork lines, or feature wallsso the panel doesn’t interrupt key design elements.

- Optional green board or cement board inserts support tougher or higher-moisture conditions without sacrificing the seamless look.

If you’re comparing options for an upcoming mixed-use development, this is the best time to request a quote for BAC-IVH or BAC-IVHFH to align access detailing with your project’s architectural and code requirements.

If you specify access doors regularly, you can also join our Pro Club to enjoy exclusive deals and benefits made only available to our members.

How Do Access Panels Impact Fire-Rated Assemblies and Code Compliance in Canada?

Access panels impact fire-rated assemblies and code compliance in Canada because any opening in a fire separation must be protected with a tested, appropriately rated access door, or the assembly would no longer meet the required fire-resistance rating.

Under the National Building Code of Canada (NBC 2020) and its provincial adaptations, fire separations are required between different major occupancies and between dwelling units and public corridors in multi-unit and mixed-use buildings.

These fire separations are built from fire-rated assemblies (walls, floors, and ceilings) that are tested and certified as complete systems, often using CAN/ULC-S101.

When you introduce an access door into one of these assemblies, several things become critical:

- The access door must be appropriately fire-rated: Any access panel in a rated wall or ceiling must carry a fire-resistance rating that matches (or exceeds) the required rating for that assembly.

- The entire assembly (not just the door) must function as a cohesive system: Framing, fasteners, insulation, firestopping, and the access panel must all be detailed in a way that preserves the tested performance. A certified fire-rated door installed with incorrect framing or incomplete firestopping can still compromise the fire separation and lead to compliance issues.

- Mixed-use occupancy lines become sensitive: NBC provisions for separation of major occupancies (for example, between a Group C residential component and a Group E retail or a storage garage) often require higher fire-resistance ratings at these interfaces. This makes the selection and detailing of access doors at those locations a key part of code compliance on high-rise and mixed-use projects.

Frequently Asked Questions on Seamless Access Panels in Canada

Where are seamless access panels most useful in high-rise and mixed-use projects?

Seamless access panels are particularly valuable in public corridors, lobby and amenity ceilings, condo suites, retail front-of-house areas, and any space where clean design and regular access are crucial.

Can I standardize one access panel model across multiple wall types?

Often, yes, especially with versatile drywall inlay models like BAC-IVH and BAC-IVHFH that can be sized and detailed to suit different non-rated assemblies. For fire-rated wall assemblies, always verify that the selected fire-rated model matches the tested assembly and rating requirements for each location.

Do seamless access panels help with lifecycle maintenance planning?

Yes. Research on lifecycle and maintenance planning shows that accessible, well-planned service points reduce disruption and cost over the building’s life because equipment can be reached and replaced without damaging finishes.

To Sum It Up

Seamless access panels help you protect design intent, support code compliance, and simplify long-term maintenance at the same time.

When you coordinate architectural access panels early, you avoid last-minute surface-mounted fixes, lower the risk of issues related to fire separations, and maintain walls and ceilings that look clean and consistent.

If you’re designing a new mixed-use project, it makes sense to define your seamless access points from the outset, instead of scrambling for solutions at the end of the project.

Ready to build discreet, compliant access into your next project from day one? Contact our team or call +1-888-327-5471. We’ll help you choose the right concealed access doors for your next high-rise or mixed-use project.