Drywall Inlay vs Flush Access Doors: Which Installs Faster & Finishes Cleaner in Commercial Interiors? Posted by Best Access Doors Canada on 19th Feb 2026

In commercial interiors, drywall inlay access doors typically offer better finish quality, while flush access doors often provide faster installation.

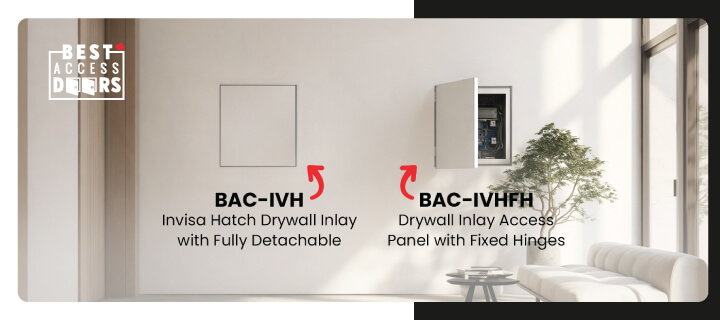

Drywall inlay models (like the BAC-IVH) are ideal when you want access points to blend almost invisibly into the wall or ceiling, whereas flush access doors (like the BAC-UHF) are better when you need a straightforward, durable opening with fast, predictable installs.

In this guide, we’ll compare both access doors to see which one installs faster, how they affect finishing and paint quality, when to choose one over the other, and how BAC-IVH and BAC-UHF often perform in commercial jobsite conditions.

What Is the Difference Between Drywall Inlay and Flush Access Doors?

Drywall inlay access doors integrate the access opening directly into the gypsum board, while flush access doors create a finished, framed opening that sits flush to the surrounding surface without needing mudded flanges.

Drywall inlay access doors use a welded aluminum frame that accepts a ½" or 5/8" drywall insert. The panel is designed so that only a slim 1/16" reveal remains visible, which allows the access door to blend almost invisibly into non-rated walls and ceilings.

Flush access doors, on the other hand, are universal steel panels that sit flush to the frame and surface but keep a visible, clean metal face.

Instead of inserting drywall into the door leaf, flush access doors give you a robust metal face with a pantograph hinge for controlled opening and a standard screwdriver-operated cam latch (with multiple lock upgrade options). Paired with a concealed flange, this design helps your team install the panel quickly and keeps finishing work to a minimum.

Check out our drywall inlay and flush access door models for commercial interior projects if you’re comparing options for an upcoming fit-out.

How Do Drywall Inlay and Flush Doors Affect Finishing and Paint Quality?

Drywall inlay access panels often act as clean finish access doors and generally deliver the most seamless appearance for high-end finishes, while flush access doors offer reliable paint performance with fewer paint and texture matching risks.

With drywall inlay access doors:

- The face is the same gypsum product as the surrounding assembly (½" or 5/8" drywall), so you can apply the same taping, mudding, sanding, and paint system.

- The 1/16" reveal and hidden hinge help avoid shadow lines and visible hardware. Only a thin joint needs to be treated and painted.

- The perimeter seal and welded aluminum frame help limit hairline cracking at the opening by stabilizing the assembly and controlling movement.

Where drywall inlay doors demand more from your team is quality control. If the opening isn’t aligned with the framing, or if the insert isn’t handled carefully during finishing, you can end up with chipped corners or visible ridges.

With flush access doors for commercial interiors:

- You’re painting a pre-finished steel surface rather than gypsum, typically starting from a high-quality white powder coat primer.

- The hidden flange eliminates the need to tape and mud around the frame, which reduces the risk of edge cracking and repeated touch-ups.

- Because there’s no drywall insert on the leaf, there’s less chance of joint compound chipping at the dooredges when the panel is opened and closed.

Flush access panels will always look like a visible metal door in the wall or ceiling. That’s usually fine in corridors and service zones, but it’s less ideal on feature walls where architects want access doors that blend in and are barely noticeable.

Which Access Door Type Installs Faster in Commercial Interiors?

On most commercial interiors, flush access doors with a concealed flange tend to install faster if the access door type is chosen late. In other words, after drywall sequencing is already complete.

In those situations, your crew can simply cut the opening, fasten the concealed flange, and touch up the edges. By comparison, installing a drywall inlay at this stage can be fussier and more disruptive.

However, if the decision is made early and coordinated with framing and drywall work, drywall inlay doors can be installed and finished with the rest of the board and in the same mudding and sanding passes.

In that scenario, they can be just as efficient as flush doors, sometimes even better in high-finish areas because you’re not coming back to do separate framing or patching around a metal face.

When Should Contractors Choose Drywall Inlay Versus Flush Access Doors?

Contractors should choose drywall inlay or flush access doors based on how visible they want the access point to be, how often it will be used, the timing of the specification, and the finish tolerances on that wall or ceiling.

Choose drywall inlay access doors (like the BAC-IVH) when:

- You’re working on high-visibility walls and ceilings in lobbies, reception areas, hospitality interiors, or executive offices.

- Architects are targeting near-continuous surfaces, with Level 4/5 finishes and strict finish coordination around texture and sheen.

- You want the option to create tile-ready or specialty finishes on the panel itself.

- Space constraints demand a fully detachable door leaf for wider access during commissioning or maintenance.

Choose flush access doors (like the BAC-UHF) when:

- You’re in corridors, mechanical rooms, and service spaces where a clean, steel face is acceptable.

- Access panels will be opened frequently by maintenance teams, making durability, hinge performance, and latch reliability higher priorities than invisibility.

- You need a labour-saving install that doesn’t require mudding a flange or integrating drywall into the panel

- Moisture and corrosion resistance matter (e.g., near mechanical equipment or in damp areas), and you want options like stainless steel or neoprene gasketing.

Related: Why Do Seasoned Contractors Reorder the Same Access Panels Every Time?

How Do BAC-IVH and BAC-UHF Compare in Real Jobsite Conditions?

On jobsites, the BAC-IVH Invisa Hatch Drywall Inlay with Fully Detachable is often ideal when you need a cleaner look and easier access in tight spaces. Meanwhile, the BAC-UHF Aesthetic Access Panel with Hidden Flange is usually a better fit for faster installs, durability, and repeatability across standard commercial interiors.

Let’s look at both panels in detail to see where each one fits best.

BAC-IVH Invisa Hatch Drywall Inlay with Fully Detachable

On commercial interior fit-outs where architects want “invisible” access, the BAC-IVH access door helps your team:

- Maintain continuous wall and ceiling lines, with only a narrow reveal showing once painted.

- Work efficiently around congested ceilings or narrow corridors thanks to the fully detachable panel door and integrated safety system on larger sizes.

- Keep maintenance user-friendly with a pressure-assisted, push-to-latch mechanism that doesn’t require special tools for basic access.

- Upgrade security or control with alternate latch options, including screwdriver-operated cams and keyed

BAC-UHF Aesthetic Access Panel with Hidden Flange

On projects where time and consistency are a priority, the BAC-UHF access door gives crews a universal, non-rated solution that:

- Installs quickly using the 7/8" concealed flange, embedding cleanly into drywall or masonry without taping and mudding a flange.

- Performs reliably in higher-use areas thanks to its 16-gauge cold-rolled steel construction and exclusive concealed hinge design.

- Offers moisture and corrosion resistance out of the box, with stainless steel upgrades for more demanding environments.

- Keeps interiors looking orderly with an architecturally pleasing flush-to-frame appearance and concealed hardware.

Request a quote for BAC-IVH or BAC-UHF based on your installation and finish requirements so you can align the right panel with each interior zone.

Also, if you regularly source access panels across multiple projects, consider joining our Pro Club to unlock member perks, streamlined ordering, and priority support.

Frequently Asked Questions on Commercial Interior Access Panels

1. What is a flush access door?

A flush access door is a framed metal door that sits level with the wall or ceiling surface, creating a clean, low-profile opening. Models like BAC-UHF install quickly and provide durable, repeatable access points for non-rated commercial interiors.

2. What is an access panel for drywall?

A drywall access panel is an opening integrated into a gypsum wall or ceiling that allows access to valves, junction boxes, or services behind the board. Drywall inlay versions, such as BAC-IVH, use a gypsum insert so the panel can be finished to match the surrounding surface.

3. Where are drywall access panels needed?

Drywall access panels are typically installed wherever you need ongoing access to MEP services behind finished walls or ceilings. These include mechanical shafts, plumbing chases, electrical junction boxes, and control valves.

To Sum It Up

Drywall inlay and flush access doors both have a distinct place in commercial interiors. You just need to align each type with the appropriate area and construction stage.

Drywall inlay access doors, such as the BAC-IVH, give you the most seamless, “invisible” result when planned early and finished alongside surrounding gypsum.

Flush access doors, like the BAC-UHF, deliver faster installations and robust performance when decisions happen later or when durability and easy service take priority over visual blending.

If you’d like help matching the right access door to each interior zone, contact our team or call +1-888-327-5471 to review your plans and requirements. We’ll recommend which access panel model best supports your commercial interior project.